Robotics for the Wholesale Bakery

Mike Rebollo

Southwest Regional Sales Manager

BluePrint Automation (BPA)

What trends in robotics characterize the systems that BluePrint Automation has developed for use by wholesale bakeries? Are these applications new to the baking industry?

There are 2 areas that we are asked to utilize robots!

First is the unwrapped product handling. This can include creating stacks of pancakes, waffles, flatbreads, pizza crusts, tortillas, etc. and then loading them onto the infeed of wrappers, or onto conveyors. Additionally, we can pick and place unwrapped products such as muffin, cookies, crackers, bars, etc. and load them into flow wrappers and clam shells. Furthermore, we can handle baked products to complete the finished product, such as a specialty cookie or a type of sandwich. Usually these projects involve high volume incoming products at rates of 200-2000+ pieces/minute.

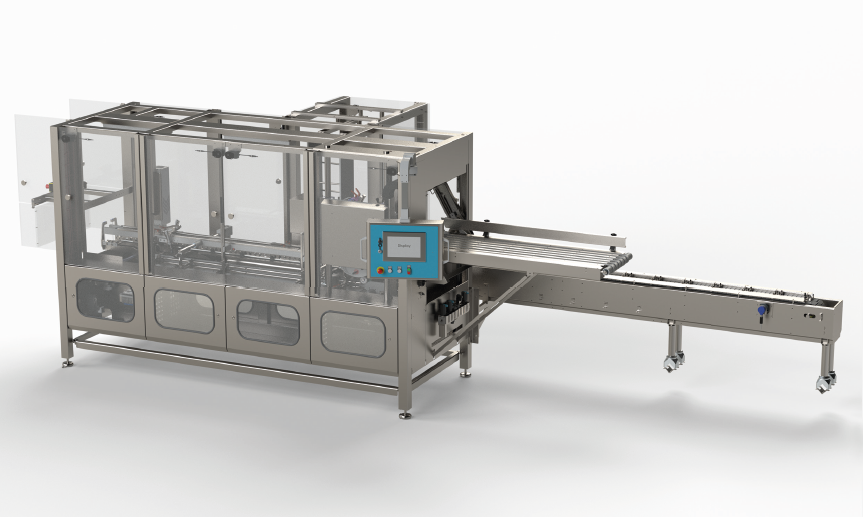

The second area that we are utilizing robots is after the product is wrapped or placed into the clamshell, or, other primary package. These projects are described as carton loading and case packing. Frequently, we are receiving product from the discharge of multiple flow wrappers. Often we are asked to load both cartons and cases. The speeds to match the production rate of the ovens, 200-2000+ pieces/min

What uses are most common? What are just now emerging? Where do you see the next range of bakery robotics developments occurring? Why?

Common uses- Pick and place unwrapped products such as muffin, cookies, crackers, bars, etc. and load them into flow wrappers and clam shells. Furthermore, we can handle baked products to complete the finished product, such as a specialty cookie or a type of sandwich.

Receiving wrapped product from multiple flow wrappers then loading them into chipboard cartons and corrugated cases

Now emerging- Although we have been installing robotic solutions for over 30 into the bakery industry, most bakeries are not utilizing them. I would say that both applications described above are still emerging within the bakery industry.

Additionally, we are getting more requests to utilize robots within the baking process such as aligning dough balls prior to the proofer, placing specialty products onto the infeed of band ovens, and other applications. We believe robots can have benefit within the pre-oven process, however, these are often unique and involve a higher level of risks. We need to look at each application to determine the viability of these projects.

Utilizing robotics in the pre-oven process will be the next major development within the bakery industry. This is occurring for a few of reasons, first is the uniqueness of the bakery products being developed. Often these products are unique and cannot be handled by a mechanical solution. A robot, with special tooling, can handle this product like a human hand would, often with more precision and higher rates. Also, the challenge of finding and retaining skilled labor will continue.

Another area were robots could be utilized is the handling of heavy bags of bakery products. A robot can easily and accurately lift and manipulate these bags.

What kind of economies — including line speeds, output rates and manpower conservation — do your robotics offer bakery users?

There are 3 primary areas were bakeries can justify robotics, and, automation in general, reduction of labor; increase output; safety. Labor costs will continue to raise for the foreseeable future. Reduction of labor is a simple calculation of quantity of people multiplied by their annual labor rate, plus their burdens. This is often the first place to look for budgeting purposes.

Increase output appears to be the greatest challenge for most companies these days. Often, we see bakeries not able to utilize their processing equipment do to a shortage of labor in some area of the process. Robotics allows these companies to handle mundane, repetitive tasks and allocate their good employees to other high skilled tasks

The handling of heavy bags of bakery products is a good example of utilizing robotics for safety concerns. A single back injury could cost a lot more than the investment of robot to do the heavy lifting.

Usually we see companies that are running multiple shifts, with band ovens running at speeds above 200 pieces/min utilize robotics.

Does your company have a test facility that can allow bakers to work with your robotics in advance of installation?

We do have a test lab at our robotics plant in Longmont, Colorado. We like to test and validate all high-risk projects. This gives us and the customer a much higher level of confidence that we will be successful on their project. Additionally, we use a robotics simulation package the mimics real world installations.