Solving Five Secondary Packaging Challenges in the Snack Food Industry

.png)

The public’s love for snacks hasn’t changed, but how snacks are packed and distributed from the manufacturing line is constantly evolving to meet consumer demand and preferences. Secondary packaging is the outer layer of product packaging that helps maintain sanitation and quality for our favorite snacks while supporting branding and shelf appeal.

The secondary packaging process for snacks comes with challenges that producers and co-packers must consider to support their strategic objectives. In this guide, we break down five of their biggest secondary packaging challenges and explain how automation can solve them. Topics include:

- How to manage a growing number of product SKUs

- Ways to make the most out of limited manufacturing space

- Building variety packs through automation on the floor or off-site

- Minimizing changeover times to increase productivity and reduce downtime

- How display-ready pallets can increase awareness in club box stores

Throughout our discussion on snack food challenges, we’ll explore various ways BPA can help you optimize your secondary packaging operations for sustainable growth in the very competitive space on the shelf.

1. Too Many SKUs

Challenges

Manufacturers and co-packers are required to pack greater quantities and variations of products.

- Extensive range of products: Each product has its own flavor variants, sizes, and packaging requirements, with seasonal preferences and styles often adding to the complexity.

- Irregular packaging sizes: Irregular and non-standard package sizes can quickly multiply SKUs, increasing line complexity and straining secondary packaging equipment.

- Market consolidation: You could be running products for our own private label in the morning and running something completely different in the evening for a customer you’re co-packing for.

Solutions

If you rely primarily on manual packing for secondary packaging, it demands significant training and resources and is difficult to manage due to historically low retention among packing staff.

Increasingly, more producers and co-packers are turning to automation to manage many SKUs with their various packaging requirements. Still, there are considerations to ensure you have machines capable of handling various case sizes and pack styles.

Starting Slow

The critical thing to remember is that you can make the transition to automation slowly as your business grows and your team becomes more comfortable. As a true partner, BluePrint Automation can consult you on any production challenge or guide you on the steps you can take as you transition toward automation.

Semi-Automation

Our Collator 200 is a low-cost semi-automatic machine that can stand bags up to present them in a vertical format for human packers to pack in a case. This will immediately increase production and flexibility on your line as it eliminates pack-off tables and cuts out a step for the packers.

Robotic Case Packing

As you get more comfortable with automation, you can add speed and precision to your secondary packaging process. For example, a Spider 200 is an excellent intermediary step toward full automation. It is equipped with our high-speed collation systems and has on-the-fly picking and placing capabilities to handle various SKUs.

Full Automation

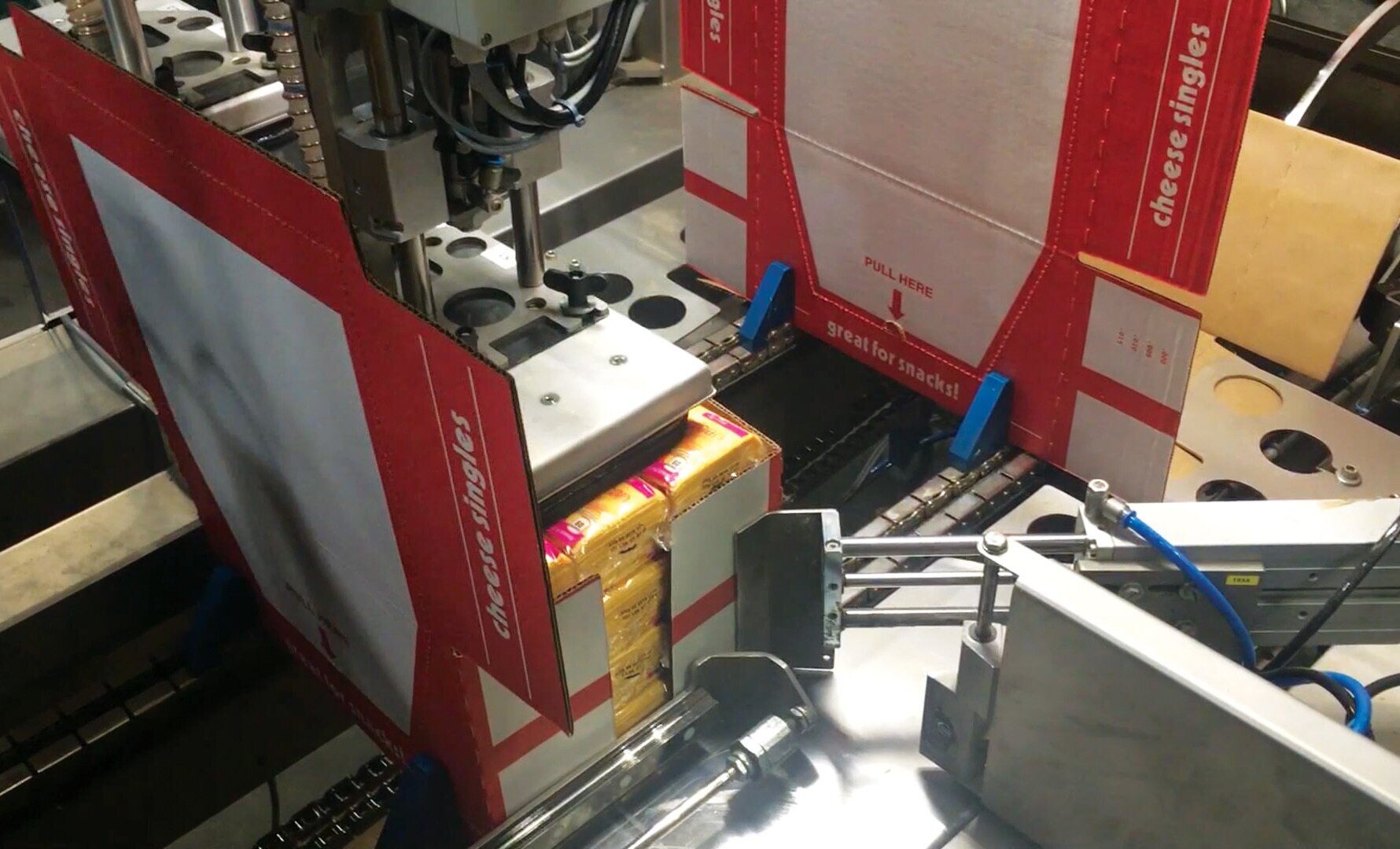

We are constantly challenging our equipment's minimum and maximum ranges to handle more products and packaging types when you’re ready to make the jump to automation. An example of this would be the Spider 200i, an all-in-one system capable of erecting, loading, and closing your case. To take it a step further, you can also think about integrating our automated case blank distribution and loading system to get corrugate off the floor and reduce potential safety hazards.

2. Limited Floor Space

Challenges

Floor space is a massive challenge for manual and automated secondary packaging operations.

- Inefficient use of space: Manual processes need significant labor to perform all the steps, from erecting the box to sealing the fully packed case. And many automated packing solutions require substantial floor space to operate, even if they reduce labor needs.

- Faster upstream loading: Current baggers are running so much faster than they used to run (up to 200 bags a minute), and you really can’t accumulate bags, so your secondary packing operations must keep up even if floor space is limited.

Solutions

Remember, not every solution will work or even fit your floor space. You should consult an equipment manufacturer or integrator when adjusting your layout to accommodate new equipment. One benefit of working with BluePrint Automation is that our sales team comprises engineers who work with customers daily to create a layout that best utilizes their floor space.

For example, the Gantry 200 is designed with snack food plants in mind for its versatility and small footprint. It can even fit under mezzanines found in many snack processing plants while delicately handling bags of chips and other fragile products commonly produced in the snack food industry.

Consider your specific needs and pain points concerning floor space as you work toward finding the best solution for your lines.

3. Variety Snack Packs

Challenges

Consumer preferences are shifting towards convenience and variety, creating some logistical challenges for manufacturers.

- Human errors: Traditionally, producers and co-packers have relied on hand packers to go through thousands of bags in bulk for variety pack assembly, which is time-consuming and lends itself to wrong product counts and other errors.

- Outdated capabilities: Legacy equipment can fall short when packing variety packs because it wasn’t designed for precise product counting, sequencing, and placement to accurately assemble multiple SKUs into a single case.

Solutions

Our sales engineers can help you determine the best solution among the ones listed below to meet your needs and space constraints. We will consider the product volume, types, pack pattern, and other factors that can impact your variety pack assembly.

Count and Batch System with Drop Chute

This solution is ideal for jumble packs that don’t require precise product orientation and is often the simplest, most effective approach for variety packs. Products are fed into feeders and conveyed into separate lanes by flavor, then dropped through chutes into a case traveling on its own conveyor, stopping at each station to receive the correct mix.

Traditional Case Packer

A traditional case packer loads products into precise, predetermined patterns rather than jumbled arrangements. Using an organized infeed system and conveyors, it guides specific flavors into fixed positions within the case. While more advanced than simple drop packing, it lacks the flexibility of robotics and is best suited for straightforward variety packs with a few flavors and consistent orientation requirements.

Robotics with Vision

One of our core competencies is integrating vision systems and robotics for variety packs. Our Spider V series features our vision technology that can be programmed to pick and pack selected snack bags in any pattern into a master bag or carton for various types of multipacks. This variety pack solution creating a multipack in cartons, showcases our flexibility and ability to meet evolving packaging preferences.

For more information on these solutions, check out our guide to snack variety packs and automation.

4. Changeover Time and Maintenance

Challenges

Changeover time is a constant issue in the snack food industry, as you must adapt to shifting production requirements and accommodate diverse product lines.

- Too many changeover parts: Some changeovers require carts to hold the necessary parts to change recipes on the line. These carts have to be stored somewhere on the floor for easy accessibility to avoid additional downtime.

- Equipment breakdowns add to downtime: Because downtime directly impacts productivity, snack manufacturers need machines that are easy for operators to maintain and equipped with safeguards to prevent issues caused by loose product, dust, and contaminants.

Solutions

You can implement some practical strategies right now to reduce changeover times. One way is to review your production schedule to see if there are opportunities to group similar production runs together and reduce repetitive tasks. Another is to standardize your SOPs and ensure all operators are trained on these procedures to add consistency to your processes.

Upgrading Your Machines for Simpler, More Efficient Changeovers

You will likely see the most impact and improvement through equipment upgrades and automation. Over the past decade, BPA has pushed to minimize change parts and points on our equipment to reduce changeover times and complexity. This has benefited snack manufacturers in a number of ways:

- The size and weight of the change parts used on our machines are significantly lighter and smaller. Technicians can ditch the cart and carry all the parts they need in their hands for faster and more efficient changeovers.

- We’ve streamlined control platforms and reduced system complexity to simplify operation and improve user adoption. The result is less downtime and reduced reliance on highly skilled technicians for changeovers and routine maintenance.

- Clean-up is also easier during changeovers to avoid longer and costlier downtimes. We added covers to our machines to prevent dust accumulation and loose product from getting into them.

5. Display-Ready Pallets

Challenges

Display-ready pallets (DRPs) are prepacked for quick transfer from the distribution center to the sales floor, simplifying restocking while showcasing branded displays that drive impulse purchases. But this convenience also adds complexity for snack manufacturers.

- Assembling DRPs is resource-intensive: The process for DRP assembly is heavily manual, requiring significant time and space.

- Product damage and handling: Pallets need to be sturdy enough to prevent crushing, shifting, or tipping during shipping, handling, and on the sales floor.

Solutions

Reducing manual labor is essential as more stores request DRPs to enhance operations and marketing. Optimizing your processes and scheduling to accommodate DRPs will help, but finding an alternative way to construct a DRP-style display will likely yield the best results.

Our Unique Approach to DRPs

BPA has found a way to automate this process. By using stacked three-sided display boxes, producers can replicate the traditional DRP while automating the assembly process. We use our Gantry 300, which can run vertically and horizontally, to facilitate these display case runs.

If you are considering ways to run DRPs in your facility, this may be a viable option to keep in mind. Even if now is not the right time for an automated solution, we can consult you on other methods and packaging options to support the demand for DRPs.

Wrapping Up

The snack food industry is ever-changing, with new products and packaging to meet consumer preferences, industry trends, and technology advancements. Automation has improved many challenges impacting the snack food industry, but many options exist.

We can tailor a solution to your unique needs if you’re looking for ways to add automation to your secondary packaging process. Let’s work together and explore the endless possibilities to increase speed, improve flexibility, and stand out in your industry. Contact us today to get started.