4 Machines Helping Automate the Bakery Industry

Sliced bread. A simple everyday product that’s omnipresent in every home and is often overlooked. It was considered a manufacturing miracle when it was first introduced in shops. The product was old; however, the concept and processing were re-imagined.

The staple no longer needed to be kneaded, proofed, raised, marked, and baked. One could now buy bread at the corner bakery or supermarket, pre-sliced and ready to go.

The well-known term ” best thing since sliced bread” speaks to how the simple baked product became the symbol of industrialization and convenience.

How Can Automation Help Bakeries?

That’s exactly the benefits automation can leverage for your baked product brand. Robotics and automation in your factories can elevate your existing product and make your brand known for convenience and quality.

Here are some benefits you stand to reap from automating your bakery business:

It Makes Economic Sense

Calculate how much you pay for factory workers. Factor in the rising cost of labor and global labor shortages. Automation saves you the cost of hiring, training, and retaining labor. Mundane tasks can be re-assigned to robotic machines that need little to no supervision once calibrated.

Moreover, automation is an investment that soon pays for itself; everything you make after that, is pure profit. Modern case packing systems are the more efficient and economical option.

It’s More Efficient

Robotic case packing systems or tray packing machines don’t go on vacation or require sick days. They can pretty much work 24 hours. Secondly, making mistakes, a purely human quality, also costs companies heavily in lost revenue and resources.

Put simply, automating parts of your production line results in more productivity for your brand. It’s also a great way to boost the productivity of your staff by freeing them up from humdrum daily tasks. Automation makes your factory safer, more efficient, and your products more reliable.

Here are some machines changing the standard ways of bakery production and streamlining the baking process:

Wrapper Loading Systems

Blueprint automation has packaging solutions for all of your products. The packaging process starts with primary packaging as soon as a finished naked product heads down the assembly line. The wrapper loading system can be fitted with various customizable pick heads depending on the product it’s meant to be placing onto the wrapper loader.

The machine then loads the single product into its wrapper, hffs machine or stacks them together before inserting them into bulk packs. The wrapper loader can load at high speeds and incoming product can be random.

Semi-automatic Case Packing Systems

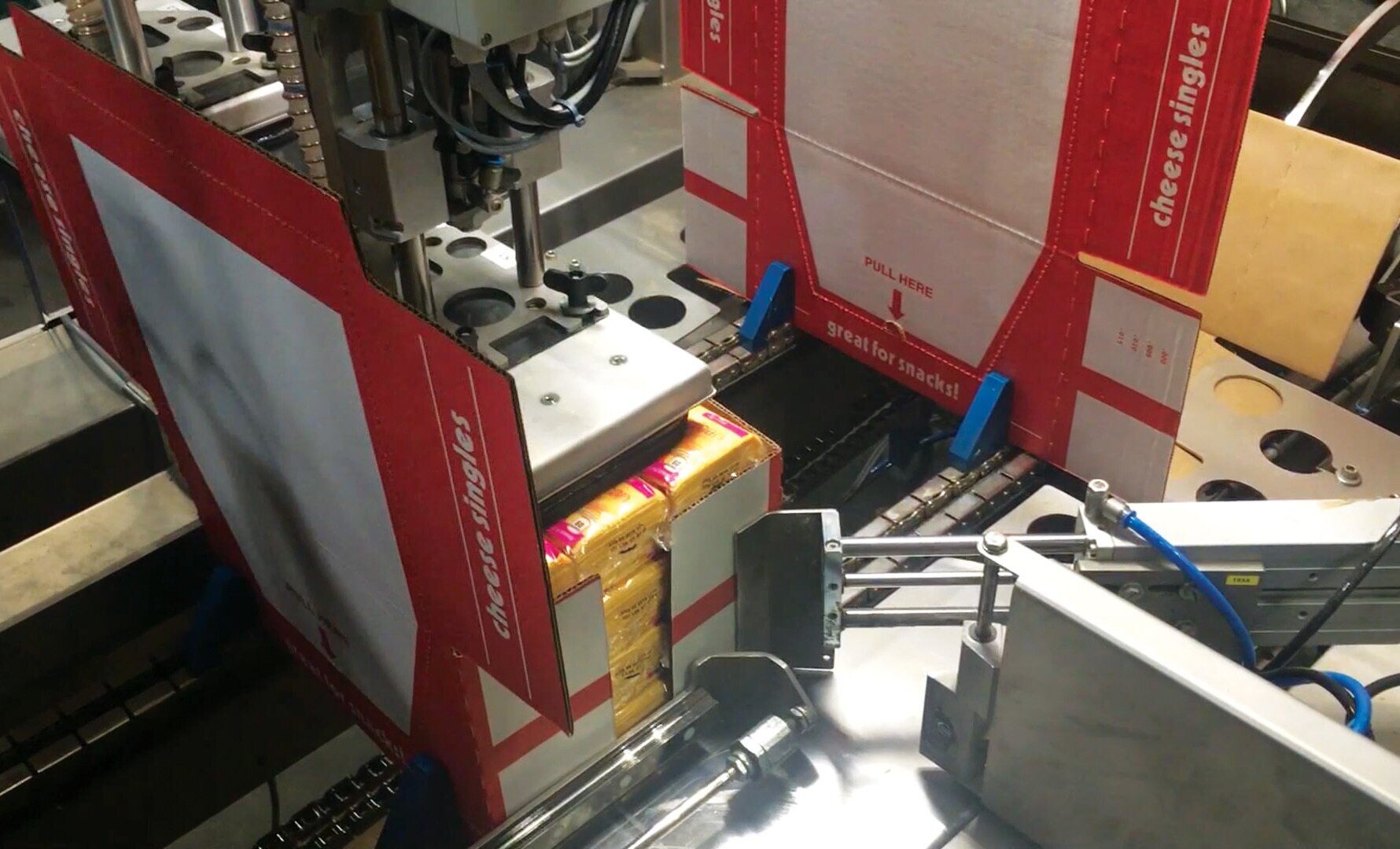

Case packing systems and tray packing machines are a secondary packaging necessity at bakeries. The Spider 100 case packer by Blueprint Automation is a horizontal case packing system that fully automates the product loading process. It's great for bags, pouches, cartons, trays and more!

The Spider 100 system is an easily customizable smart machine that can be calibrated to work well with your current assembly-line machinery.

Vision Guided Case Packing Systems

The Spider 300v gives you even more choices for safety and quickly packaging your finished products in secondary packaging. The additional benefit of a vision-enabled case packing system is that it can receive random product from bulk.

The Spider 300V is a two robot dream team that can pack horizontally and vertically. Its efficient packing means more calculated use of space for each carton in less time.

The system is designed to pack for bulk and single-piece buyers, with less changeover time. It can be further customized to suit the specific requirements of your brand.

Pick and Place Robots

Pick and place machines are typically used for loading your packaged products into secondary containers (secondary packaging). Basically, this machine has an application wherever products, after packaged, need to be case packed for shipping. Automating this part of your bakery production line means a more efficient and flexible packaging line.

Saving your company from damaged product and conserving time is easier with automated pick and place robots such as the Gantry 200. The Gantry System is ideal for placing packed bakery products into trays or cartons. Explicitly designed to handle fragile snack and bakery items and speed up the process of secondary packaging in plants.

Change-over between handling bags, trays, boxes, or wrapped goods is no challenge for the Gantry 200. Changeover can typically be completed in under 10 minutes.

Ready to Level up Your Packaging Game?

Case packing systems play a major part in how your finished product will look on shelves and how it is received by your consumer’s. BluePrint Automation offers tailor-customed solutions for your secondary packaging process.

The bakery business is a highly competitive one. Automating your assembly line is undoubtedly a huge step. One that can help you stay ahead of your competition while controlling production costs and putting out consistently high-quality products.

Blueprint Automation is committed to making this transition as seamless as possible for your company. Automation is an investment in the future of your brand. To learn more about what case packing system or tray packing machine will be best suited for the specific needs of your products, contact our representative today.