Common Tray Packing Machine Problems and How You Can Avoid Them

Automated machinery has revolutionized the entire product packaging process. It has many plus points to offer your company from streamlining to cost-saving. But automation requires the entire assembly line to work as one unit, like clockwork.

That’s only possible when each piece of equipment performs its tasks without a glitch.

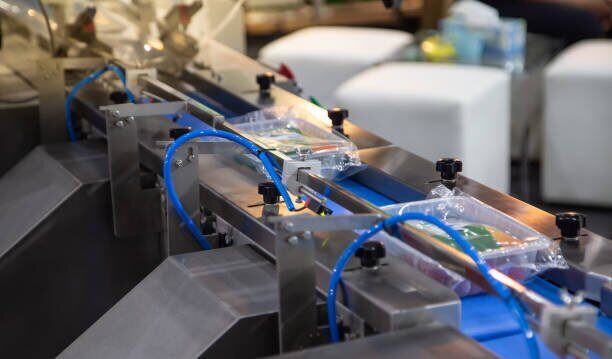

Tray packing machines stretch and seal thin plastic lids on trays containing different food products. That includes a wide array of fresh produce and frozen, cooked, and semi-cooked meals. Because of their ability to heat-seal a versatile range of trays, tray packing machines are an ideal primary packaging option for various products.

Once done manually, most tray sealers today are fully automated and made to handle large volumes per day. Modernization in tray packaging technology has enabled innovation in edible products. It has contributed towards bringing us the variety in the pre and semi-cooked food categories we see on supermarket shelves today.

Tray packaging machinery is vital to most assembly lines handling edibles in any modern-day factory. That means that any issue with the tray packing machines could mean wasted finished products that only have short time windows to be packaged and stored before spoiling.

Common Tray Packing Machine Problems

Glitches in your tray packer will disrupt the entire pre-defined progression of products down the assembly line. Educating yourself about some of the more common tray packing problems can help you create contingency plans in case of any breakdown.

That way, you can take a more proactive approach toward keeping your factory running instead of trying to fix the issue after a major breakdown halts the production of your product.

The core job of tray packing is to pack and seal food trays so no contaminants can get in. Improper seals can happen either because of issues with the sealing film or the material contained within the tray. Here are some common issues you may experience with tray packing machinery:

Sealing Film Issues

The material used to seal trays is often a flexible plastic film stretched and heat-sealed on top of the filled trays before heading down the line for secondary packaging. If the tray packing machine malfunctions, the seal will not close as it should, resulting in possible spillage, leaks, and contamination. Let’s look at some ways it could present itself:

1. Jagged Edges or Incomplete Seals

If the top seal looks jagged or torn around the edges, that means not enough area came into contact with the tray edge to form a proper seal. Jagged, torn, and incomplete seals usually occur when:

- The sealing temperature is too low

- Cutters are not as sharp as they should be

- The seal is not getting pressed long enough

- Something is coming between the film and tray edge, preventing the formation of a proper seal.

Most often, the tray contents can spill onto the edge and cause improper sealing. Such damaged packaging is more at risk of bursting during transit and handling.

Low sealing temperature is responsible for loose or jagged sealed edges. An easy solution is turning up the sealing temperature at 25° Fahrenheit increments till a perfect seal is achieved.

2. Film Not Feeding Correctly

Sealing film that does not come off the roll smoothly can clog up the entire machine. Layers of flat film sticking together are called ’’blocking”, and it can slow up operations and create a bottleneck.

Usually, that happens when the plastic film has been incorrectly handled, such as stacking too high or stored at high temperatures. That creates fusing between the film layers and results in whole rolls of wasted film.

The solution is to maintain the ideal temperature ranges. Both for storage and for sealing. Always store packing film at temperatures defined by the manufacturer. Make sure the stacks of film are not higher than instructed and don’t order stock more than you have the capacity to store appropriately.

3. Build-up

Build-up can happen when the sealing temperature or pressure is too high. That causes polymer build-up and can cause damage to the sealing parts. Adjusting the temperature and regular removal of build-up is are easy ways to combat the issue.

Preventive Measures to Avoid Tray Packing Issues

These were some common scenarios that cause tray packing machines to lose efficiency. it’s equally important to discuss ways to keep machinery in optimal working condition. Here are some easy measures to ensure your tray packing equipment is in top form:

1. Scrutinize All Parts and Material

Taking the time to do a quick inspection before starting operations can save you a lot of wasted time in troubleshooting problems later. Make sure you inspect all materials when accepting deliveries as well. Sometimes it's faulty material, film, or labels that are the issue, not your tray packing machinery.

2. Avoid Bottle-Necks

While not exactly an issue exclusive to tray sealing machinery, bottlenecks anywhere in the assembly line can cause automated tray packing equipment problems. Especially when it comes to perishables that can only be kept fresh for a limited time.

Adjust the pace of your assembly line and synchronize all machinery. That will ensure your whole factory works as one unit to maximize efficiency.

3. Invest in Proper Training

The personnel you count on to handle equipment needs to be appropriately trained. They should be able to calibrate equipment, software, and materials perfectly. Investing in training your team is better than spending on repairs down the line.

Final Thoughts

With so much advancement in the packaging industry, it’s essential to select a supplier that will always have your back, no matter what issues you might run into.

At BluePrint Automation, we create solutions for our clients with tailor-built equipment. Contact us now to see how our machinery solutions can help make your brand a top market competitor.