The Importance of Packaging in the Pharmaceutical Industry

Pharmaceutical packaging industries have witnessed substantial changes. Humanity’s drive to maintain good health through innovation has paved the way for companies to create increasingly effective processes in every part of the production chain.

The earliest packaging used for pharmaceuticals was made of stones. These packaging solutions were easily broken, porous, and difficult to produce. By the 17th century, the use of bottles for storing pharmaceuticals was commonplace. Glass containers offered more customization options and better durability. Today, plastics are the most abundant means of packaging for pharmaceutical products. This is facilitated by their ability to provide tamper-proof, and child-safe containers that are heat and water-resistant.

Whether they are applied by hand or preferably, using packaging automation such as a cartoner, pharmaceutical packages need to be capable of protecting them against heat and moisture. Pharmaceutical packages that fail to keep their content secure from contact with external elements make medicines prone to contamination.

Why Packaging is Essential in Drug Production

Pharmaceutical products that are not properly packaged cannot be transported or stored for use in the future. The consumers of these drugs will not be able to relieve themselves from illness. In some cases, improper packaging may result in contamination due to product handling which can, in turn, be harmful to the consumer.

Protecting the efficacy of drugs is not the only advantage of effective packaging. For a long time, manufacturers have resorted to safeguarding their pharmaceutical products from counterfeiters through the use of distinctive packaging techniques and branding. Product forging in the pharmaceutical industry is as dangerous to the health of the consumer as it is to the brand of the pharmaceutical product. Manufacturers that are able to create retail ready packaging solutions supply products that are safe, unadulterated, and able to meet the needs of their consumers.

Creating Effective Pharmaceutical Packaging

The particular type of packaging used in pharmaceutical industries depends on the nature of the product they are intended for. The advantages of any packaging solution used should fit closely to the needs of the product it is carrying.

Most pharmaceutical products have three levels of packaging. These include:

1. Primary Packaging

Primary packaging is the first level of packaging. This packaging normally has direct contact with the medicine or product it’s housing. Materials that are used for the primary packaging of drugs have significant effects on the shelf-life, and composition of the product they enclose. Examples of Primary Packaging today include vials, IV containers, and blister packs. Any substance used for primary packaging should be incapable of causing any alteration to the drug’s chemical composition.

2. Secondary Packaging

Secondary packaging is the layer of covering that follows the Primary Packaging. Manufacturers use this layer of packaging to safely group Primary packages together.

This wrap-around packaging is important for several reasons. A few of which include the provision of an extra barrier of protection and provision of rigidity during transportation. Aside from facilitating product handling, Secondary Packaging Systems are great for branding and communicating instructions for storage.

3. Tertiary Packaging

Tertiary Packaging systems are very important for safe transportation. They protect both the Secondary and Primary systems of packaging underneath them and are a staple of every pharmaceutical distribution line.

Common Packaging Materials Used in the Pharmaceutical Industry

The most commonly used materials in modern pharmaceutical packaging industries are glass, plastics, metals, and paper.

- Glass Containers are a good choice for acidic and neutral preparations. Anhydrous liquids, and non-parenteral products are also good applications.

- Plastic containers provide a cheaper alternative to glass and metal containers. Specially formulated plastic containers intended for the packaging of pharmaceutical products are lightweight, flexible, chemically inert, and resistant to corrosion.

- Metal Containers made from aluminum and stainless steel are a good choice for both Primary and Secondary packaging of dosage forms like tablets, and capsules.

- Paper in the form of paperboard remains a significant material in pharmaceutical packaging. Packages created from cartoning are useful for creating Secondary and Tertiary packaging systems.

Key Factors to Consider While Choosing a Packaging Solution for Pharmaceuticals

1. Compatibility With the Pharmaceutical Product

Constituents of the packaging material and pharmaceutical product do not compromise each other. The nature of each product should be studied before choosing its packaging material. For instance, light-sensitive products should be paired with materials that keep light away.

2. Cost of the Packaging Solution

An unnecessarily expensive packaging solution may render your product unaffordable. The quest to minimize wastage in cost should however not compromise the quality of the product. In the case of Secondary and Tertiary packaging, the suitability of the packaging solution for printing and the over-the-counter presentation should also be considered.

3. Durability of the Packaging Solution

Using a packaging solution that is not durable will increase the difficulty in transportation. Your company may lose huge amounts on account of damaged products. Instead of serving as a healing agent, pharmaceutical products that are poorly packaged are likely to infect the patient.

In Conclusion

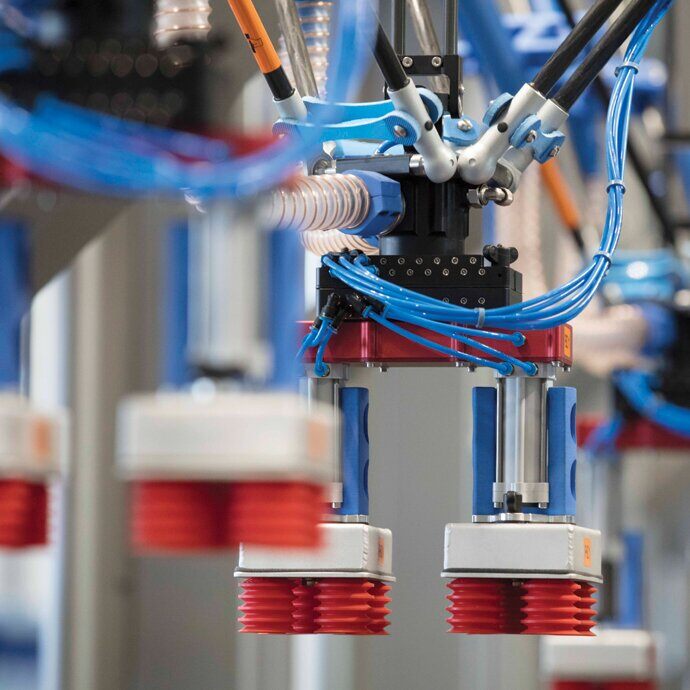

The entire packaging process of a pharmaceutical product should be executed in a hygienic process. Where possible, an automatic cartoning machine, wrap-around case packer, and other robotic packaging automation should be used to phase out human contact and maintain the purity of pharmaceutical products.

At BluePrint Automation, we have a variety of solutions to meet the needs of a hygienic and cost-effective packaging system. Contact us for any request or inquiry you may have.