Retail-Ready Packaging Trends for Improved Product Presentation

As the retail environment becomes more competitive for consumer attention, retailers are looking for new ways to increase their sales and enhance their shelf appeal. Retail-ready packaging helps accomplish these goals while relieving stress on their staff.

Retail-ready packaging is a type of secondary packaging that has been around for a little while now, starting with Walmart and later club stores. However, new trends in retail-ready packaging have made it a more popular and viable option for all retailers, and they are requesting this format more from their suppliers.

This is good news for suppliers because retail-ready packaging makes it easier for retailers to sell their products. Not only does it help retailers stock shelves faster, but it reduces handling challenges that affect how their products appear to the consumer. Finally, consumers benefit from easier access to the products they want with more options to choose from.

We will dig deeper into the latest trends in retail-ready packaging and explain how these advancements can increase sales and consumer satisfaction. First, though, let’s explore retail-ready packaging and its benefits for suppliers, retailers, and consumers.

What is Retail-Ready Packaging?

Retail-ready packaging, sometimes referred to as shelf-ready packaging, is a type of secondary packaging in which the products are shipped in the same packaging that will ultimately end up on the retail shelf or store floor. Retail-ready packaging can be found in brick-and-mortar grocery stores, club stores, convenience stores, and gas stations, serving various industries, including snacks, baked goods, fresh produce, and dairy.

There are many different types and formats of retail-ready packaging, including stand-up pouches, display trays for shelves, and larger club-style display cases. Merchandisers can quickly and easily stock these display trays and cases for consumer access without much additional handling and set-up.

As you might imagine, this packaging method reduces the packaging materials the supplier needs, especially corrugate, which is a constant goal and challenge for suppliers. It also helps retailers and their staff meet high consumer demand while relieving some of the stress created by labor shortages and ongoing supply chain issues.

Take a look at this overview of the benefits of retail-ready packaging for suppliers, retailers, and consumers that explains its growth and popularity in the last decade:

Benefits of Retail-Ready Packaging for Suppliers

- Streamlined and simplified supply chain processes, from production to distribution

- Reduced need for additional packaging materials and layers of secondary packaging

- Increased product visibility and improved presentation on the retail shelves and sales floor

- Reduced product damage and increased protection during transport

- Stronger retailer relationships and opportunities to reach new consumers and markets

Benefits of Retail-Ready Packaging for Retailers

- Reduced time and labor needed to stock shelves, allowing retailers to focus on service

- Improved shelf spacing and management and optimized product layout

- Fewer touch points during handling to mitigate tampering and human error

- Better product display and presentation to increase sales and meet uniform standards

- Faster replenishment of out-of-stock items on the shelves and floor

Benefits of Retail-Ready Packaging for Consumers

- Improved shopping experience as products are easier to find and grab.

- Better product quality and integrity from fewer touch points during transport and handling

- Easier to research, compare, and shop products at the store level

- More associates to help with service and check-out as stocking needs reduce

- Enhanced product availability and less time spent trying to find alternatives

What Is Trending in Retail-Ready Packaging?

Since retail-ready packaging has been available for some time, suppliers and retailers have had the opportunity to define their needs and determine solutions that best meet them. These trends have helped improve business processes and productivity and eliminate waste.

For example, display-ready pallets are ubiquitous in club stores, but they are difficult for suppliers to construct and require a lot of space. BluePrint Automation has developed a solution using our Gantry 300 Swing to stack three-sided display boxes to offset this format's challenges.

Sustainability

When we asked our sales engineers about what they saw on the floor and heard from our customers, sustainability was cited first. This has been a trend in Europe for some time, and it has emerged in the Americas to meet industry initiatives and customer preferences. Today, we see more compostable materials and recycled plastics and papers used for retail-ready packaging globally.

Because of our presence in Europe, we have incorporated sustainability into our machine design to ensure compatibility with these new materials. Our case packers can use many recyclable, biodegradable, and compostable materials to support various packaging types with little changeover requirements for faster, more efficient production.

Flexibility

Another concern for suppliers and retailers is meeting consumer preferences while ensuring product integrity. Case packing machines, like our Spider 300v, can use robotics to pick and place products in any pattern and load them tightly in the desired format until they’re ready to be stocked on the shelves.

Our machines are compatible with a wide range of retail-ready packaging formats, including trays, cases, and pallets for various store layouts. This ensures suppliers meet customer requirements across multiple channels to increase their availability and revenue. Our sales engineers can work with you to find the best automated solution for your needs and facility space.

Because of our experience in retail-ready packaging, we even introduced our solutions to support various industries, including snacks, bakery, fresh produce, and now dairy.

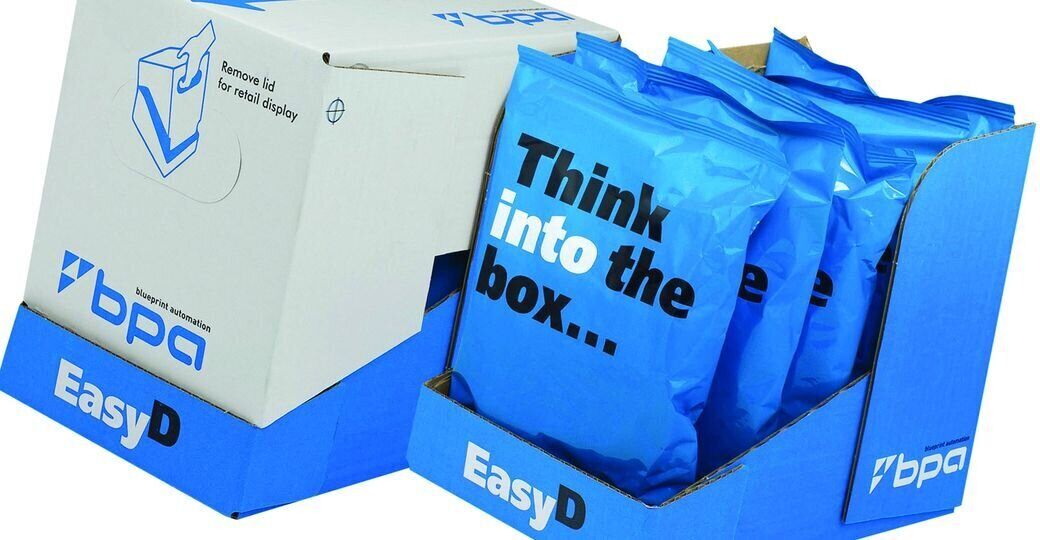

- Our Easy-D Retail Ready Case has a pre-cut front flap, reducing handling issues and creating a neat appearance on the shelf. The case features a full wrap-around design and a back wall for increased product support and better product presentation. In addition to a large offering of top load systems, the Easy-D can be erected, loaded, and sealed on our all-in-one wrap around style case packer providing additional versatility and flexibility. A smaller footprint, too!

- Our RSD Retail Ready Case also features a pre-cut front flap and is designed to erect, pack, and close like an RSC case. The RSD gives processors the ability to run both shelf ready and standard RSC on the same line.

Both cases are designed for effortless horizontal loading and shipping and can easily be converted to a shelf-ready tray with vertically standing contents. These retail-ready packaging concepts conform to strict retail requirements yet are flexible enough to meet our customers’ diverse packaging needs.

Wrapping Up

As retailer requirements and consumer preferences evolve, BluePrint Automation can help you stay on top of the latest trends and best practices to meet them. With retail-ready packaging emerging as a preferred secondary packaging format for retailers and consumers, we can ensure you have the right solution to support their needs and your production goals. Contact us today to discuss your needs and BPA retail-ready packaging solutions.