How Robotics and Automation are Changing Snack and Bakery Production

Jerry Buckley

South Central Sales Manager

BluePrint Automation (BPA)

How are robotics and automation changing snack and bakery production?

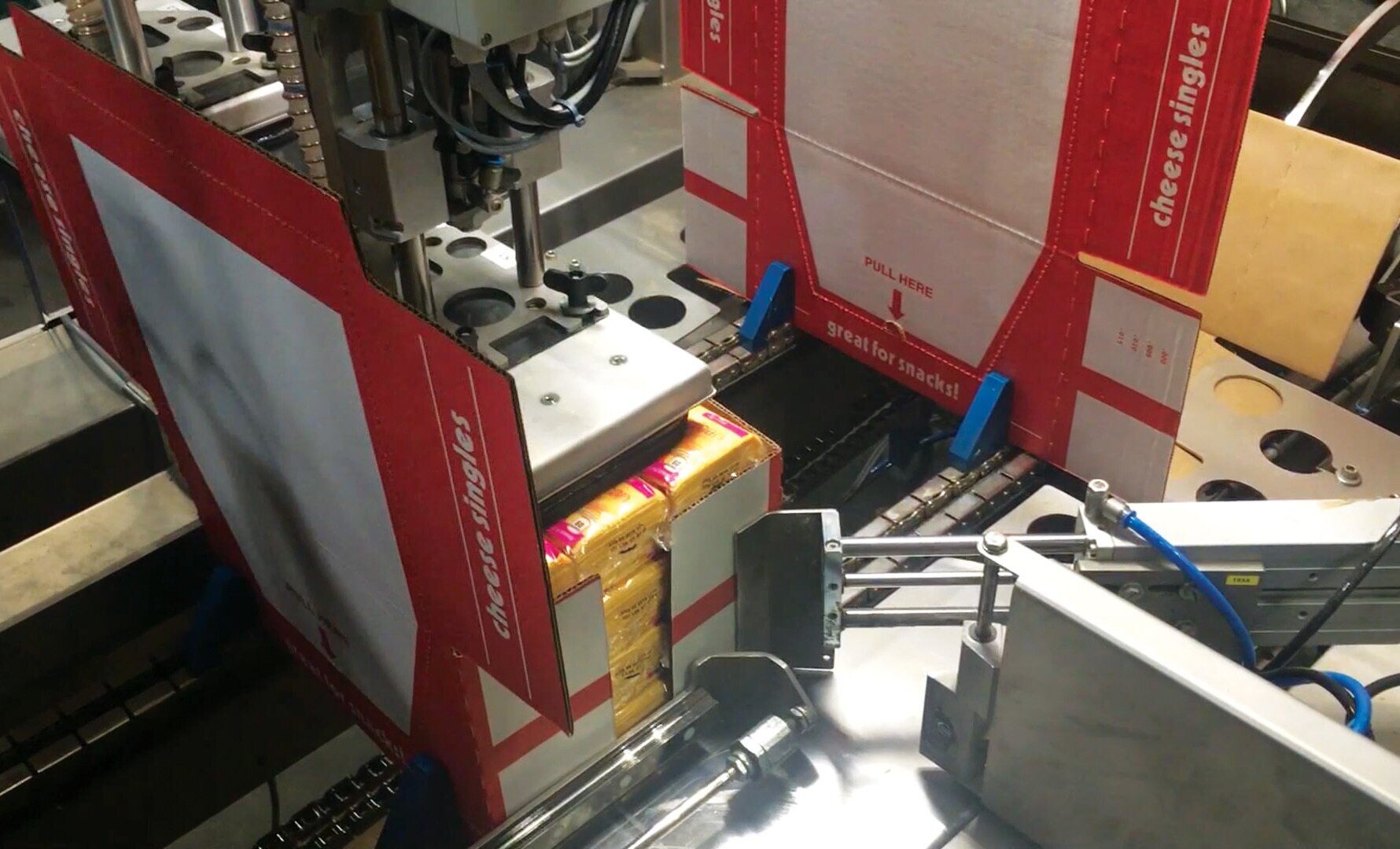

Robotics are allowing Bakeries to run production lines at much faster speeds, and with higher accuracy, than ever before while also taking up less space than an army of people would take up to perform the same task at the same high speeds.

How do data analytics, artificial intelligence and lean manufacturing factor into this equation?

With Vision Guided Robotics, typically the Vision System can very accurately review product size, shape, imperfections, and color of the products to very accurately reject those out of spec items (by not picking and placing them into their targeted destination (such as a wrapper infeed chain, tray / carton or shipping case etc.) that may be quite difficult at high speeds for people to properly inspect and remove.

How can automation help with workforce development strategies?

As Bakeries and Snack Manufacturers are currently struggling to keep production lines up and running due to staffing shortages, automation can help minimize the staffing needed on each line, so that fewer employees can be dispersed amongst the lines to simply supervise the automated production and help with the flow of materials needed to the lines.

What technological advances in these areas do you see in the near future?

The advances I see happening in the very near future is in the area of automation in getting line materials (i.e. wrapper film rolls, carton blanks and case blanks) from warehouses out to the production lines as needed to further help minimize the staffing needed to keep lines running.