9 Ways to Reduce Packaging Costs and Increase Profit

With cost pressures impacting every aspect of the market, companies are looking for ways to cut expenses, increase profits, and maintain a competitive edge without sacrificing the quality of their product.

Fast Company states that around 165 million packages are shipped each year. That means packaging and shipping take up a significant portion of the cost, making it an ideal place to start if you’re looking to cut costs.

It’s also important to consider waste from your product packaging ends up in landfills. The globe is already grappling with difficulties related to pollution and recycling.

A strategy for both vendors and transporters to cut costs and improve profit is to use cost-effective packaging materials, such as particular kinds of cartons or corrugated boxes.

In this article, you'll learn about the aspects that contribute to increased packing expenses and how to lower them.

Factors That Lead to Unnecessary Expenses in Packaging

The cost of raw materials might not be the only thing that affects packaging costs.

Other contributing factors include material durability, inefficient production models, and high shipping costs.

If you don't manage packaging materials effectively, the risk of damage increases.

A poorly designed warehouse layout could potentially exacerbate this problem. Therefore, reduce the amount of warehouse space in use is a cost-cutting measure to save money.

Check if paying for the dimensions of the packaging is incurring a higher cost than necessary. Shipping partners like UPS may be willing to work with companies to reduce costs, especially bulk orders.

Other factors to consider are the efficiency of material storage and packaging lines. Think about the following aspects:

- Do you have a well-organized storage system for your packaging material?

- Is there a way to automate your designs and allocate labor more effectively?

- How can you make product packaging move faster?

Furthermore, it is essential to ensure optimal designing and packaging methods. That technique may cost you heftier investments in trial and error, but with better designs, you can protect your product from transit damage and save money in the long run.

Sending out products to make up for damages costs more than making sure your packaging is sturdy enough in the first place. 57% of retailers say returns hamper their production process negatively.

Scrutinize your current mode of conduct to help in cutting costs. This could range from categorizing inventory to optimize storage to investing in better machinery, such as for example wrap-around case packers.

Look Outwards For Your Packaging Needs

You can opt for outsourcing processes that don’t form the core of your production line.

That technique will improve your profitability because high production volumes and corresponding amounts of packing material can be hard to handle for businesses. However, it also takes your focus away from the product itself.

Some packaging processes you can outsource are:

- shipping boxes

- corrugated boxes

- plastic bags

- paper bags

- stuffing bags

- wrap around packaging

If outsourcing isn't an option consider switching from RSC to wrap around style cases to save on corrugate cost.

Use Innovative Ways To Upgrade Packaging

If you’ve been employing the same packaging method for the last few years, you’ve probably missed some innovations in the packaging industry.

Upgrading your packaging design can give you a fresher product look and also save costs.

For example, if your product is small, padded envelopes are better than traditional boxes as they save space. That helps in reducing transportation costs as dimensions become significantly smaller.

A great way to innovate is to ramp up your packaging design. Think about themes, colors, and patterns that represent your brand image. For example, minimalist skincare packaging is a significant new trend many companies are adopting.

Also, consider that packaging is not a one-size-fits-all solution. For example, using the same box for all your products is an ineffective approach. Instead, consider diversifying your packaging size according to the size of the product.

Are you worried about the time it’ll take to package every product differently?

Let’s talk about it.

Automating Your Production Line

Automation is advantageous in several ways.

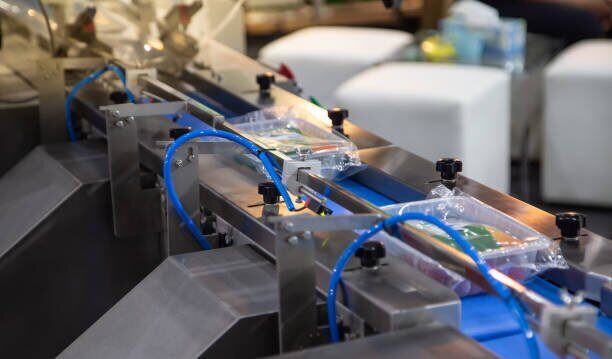

Automated machinery such as wrap-around case packers has minimal changeover time. That means you can start the production line for different products in a few minutes.

It’ll also increase output. Traditional machinery can have frustratingly slow changeover, inconsistencies in packaging, and unplanned shut-downs.

For example, wrap-around case packers can work much higher than manual labor, producing a more significant number of goods in lesser time. It can take over repetitive actions like taping, sealing, and stacking.

Automated machinery can also make corrugated cardboard, assemble boxes, and insert dividers.

Automation also allows you to protect your workforce from repetitive strain injuries and put skilled workers to better use.

Decide Which Industry Trends Works Best For You

Read up on the packaging industry for new trends, especially when it comes to changes in your particular sector. Then, focus on finding R&D efforts to figure out packaging that is sturdy, light, and eco-friendly.

Such innovations generally boost sales.

For example, eco-friendly and recyclable packaging builds a great brand image and is better for the environment. In addition, 74% of customers will agree to a higher cost in exchange for sustainable packaging. Hence, investing in sustainable packaging will increase your clientele, help you make more money, and help the environment.

Another example is personalization, which 70% of marketers believe leaves a lasting impression on customers. For example, Coca-Cola’s “Share A Coke” advertising campaign is highly successful because it allows people to relate to their product.

We know that the look of packaging determines how people feel about products. But, unfortunately, some packaging trends don’t work for that very reason. For instance, misrepresenting the amount of product or what it can do can be a turn-off.

Trial-and-error can make you discover raw materials that are more resilient to transportation damage, cutting costs on refunds. It can also protect you from making unsuitable investments.

In Summary

Rethinking your current production line for cost-cutting measures can be challenging.

A great place to start is with end-of-the-line tasks, such as packaging.

Thinking about redesigns, lowering plastic usage, outsourcing complex packaging, and amplifying research efforts can all help you reduce costs for your business.

If you’re ready to optimize your packing process, contact us today for a complete packing solution.