4 Things to Consider Before Investing in Case Packing Machinery

When it comes to choosing case packing machinery, research is key. Always vet all potential suppliers and machinery models/types carefully.

Before you start shopping for case packing machinery for your brand, it’s vital to answer some basic questions about your specific product needs. Determine what goals you expect to meet by adding new case packers into your production line. Clarifying these get-go expectations can potentially save you thousands of dollars worth of wasted resources.

Here are four main things to consider while selecting the right case packing machinery:

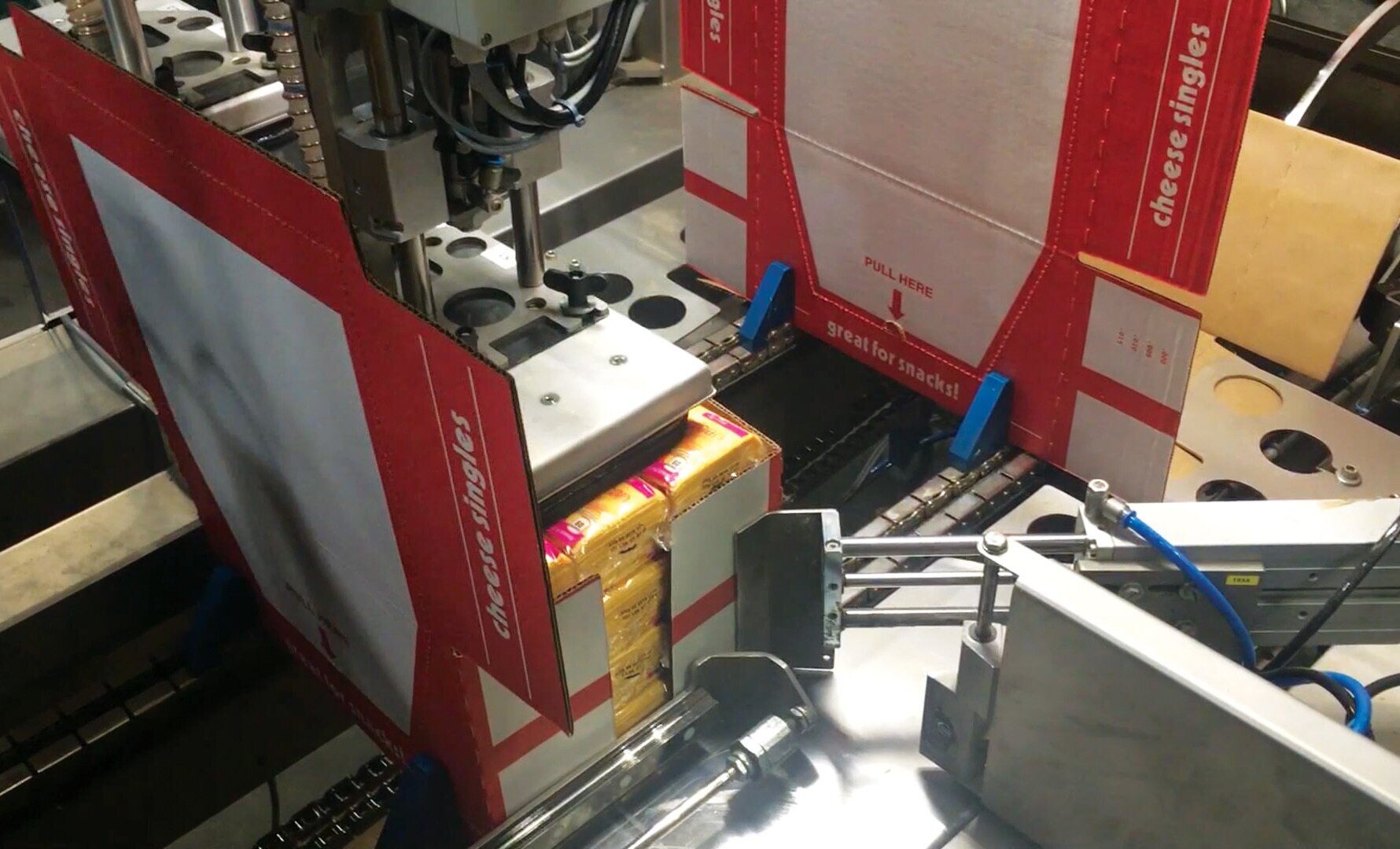

1. The Product You Need to Package

The type of machinery you require will mainly be determined by the type of product you need to package. Here are some main considerations regarding your product:

Safely Guidelines

Some products have specific requirements and will need to meet different regulatory guidelines. Educate yourself on all the health and safety requirements set by regulatory bodies in your area. Make sure you select a case packing machine that can package your product in accordance with these laws. An example could be a full wash-down stainless steel system for fresh ready to eat food lines.

Specific Product Requirements

Keeping these factors in mind will ensure that you choose equipment that suits your product specifications best:

- How many packages per minute are you wanting to pack?

- How do you plan to ship and display your product (i.e. RSC, Shelf Ready Display)?

- What are the exact dimensions of your product?

- Does the product's secondary packaging work well with its primary packaging?

All of these factors will need to be accommodated by the case packer you bring into your production line.

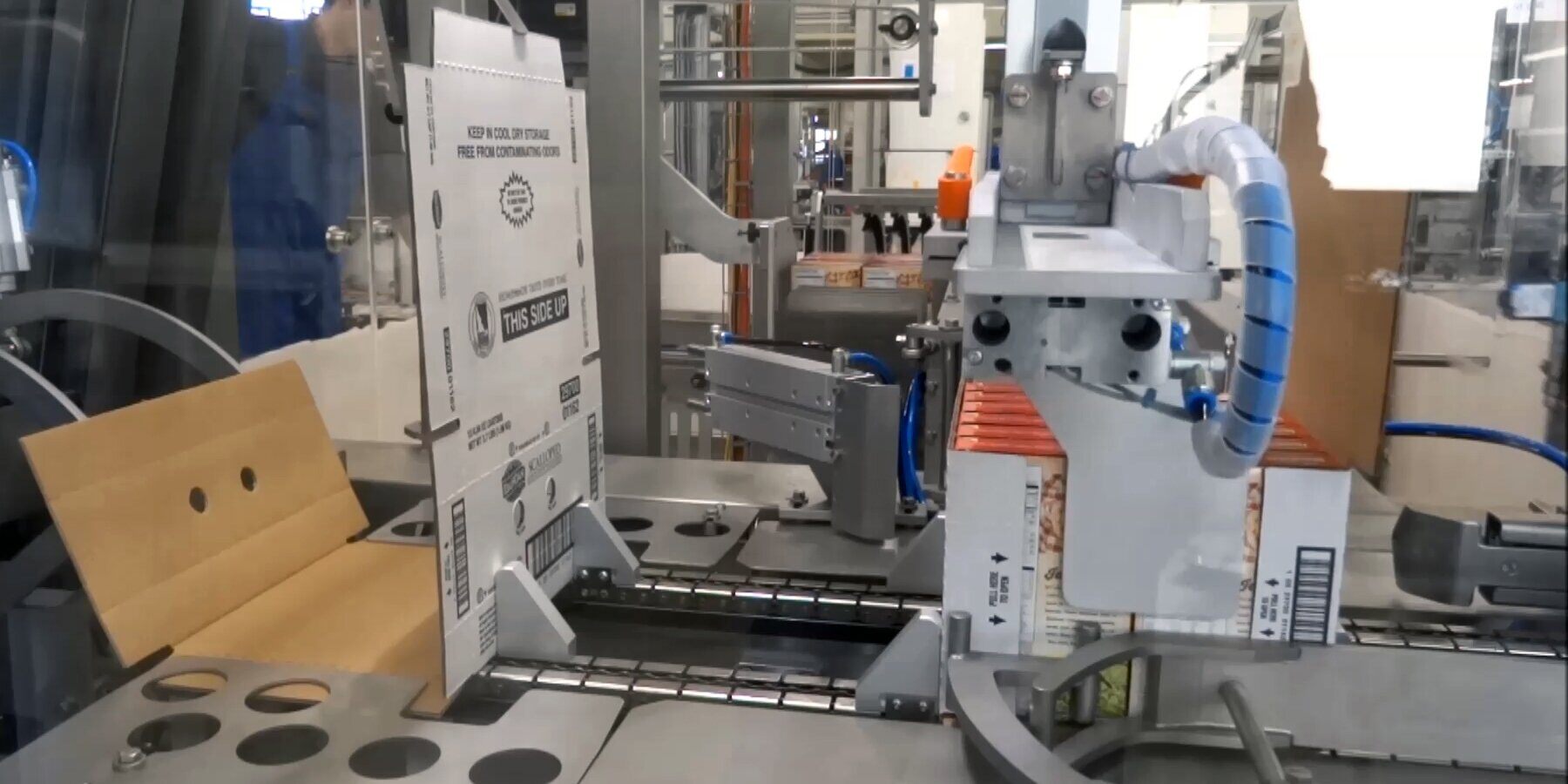

2.Compatibility With Your Assembly Line

Adding on new case packing machinery is great, but it will have little benefit if it’s not a good fit with the current assembly line at your factory. That’ll depend on your existing machinery layout and its space requirements. Here are some dynamics to configure before you order new case packing equipment for your factory:

- Nature and model of current machinery.

- Your factory layout and floor plan.

- Energy requirements of any new machinery you wish to add on.

- Dimensions of your current machinery and how new machinery would be fitted in.

- The general flow of the assembly line.

- How much mobility does your factory floor plan allow for the new and current machinery?

3. Lead Time

Sourcing the raw material required by any new case packing system will enevitably affect your lead time. Covid-19 has disrupted many supply chains and reinforced the importance of sourcing available raw materials. Be sure to plan accordingly when sourcing new case packing equipment.

4. Printing and Branding

Secondary packaging done by case packing machinery might be the last stop in the production line for the product. But it’s the first thing your customer will see and so, it needs to be impactful.

Consider printing and labeling as part of your case packing purchase.

Wear and Tear Endurance

The amount of handling and travel your product’s packaging needs to sustain in its journey should also be factored in. Use packing material that can withhold potential rough handling, bumps, and scrapes along the way. You need machinery that can seal, fold and wrap your product correctly as well.

Up Your Case Packing Equipment

Now that you know what to look for in case packing machinery for your company, it's time to get ahead of the competition and get the perfect case packing system custom-made for your product.

Our super helpful representatives at BluePrint Automation will help you select the system right for you and answer any questions you might have.